Understanding the Mechanics of Electric Vehicles: Division Deep Dive

Battery electric vehicles (BEVs) are one of the most frequently discussed topics in the automotive field and among the American society. As the consciousness and consideration for the global climate issues are under ascending scale and with the advancements of peoples’ demands for the greener life styles, EVs are not just simply a trend anymore but rather the future development of mobility. The following mechanical examination of the aforementioned machine will involve explaining how an EV works, the mechanics of it, and the possible prospects for its application as a mechanical engineer.

The Mechanics of Electric Vehicles

Perhaps, though, it is best to know the basic understanding of ‘How Electric Vehicles Really Work’ as its mechanics will be crucial in the years to come.

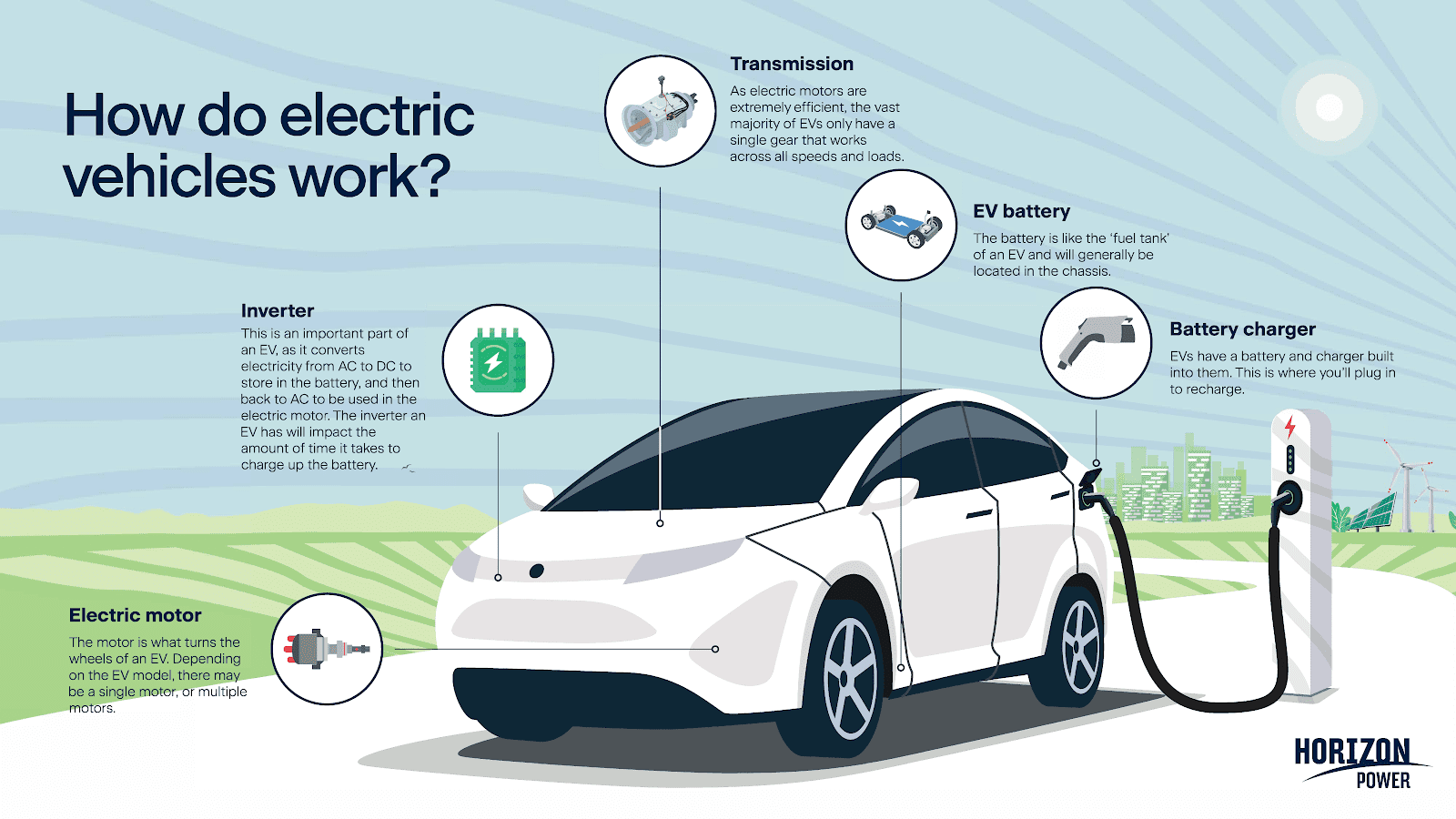

At the heart of every electric vehicle is its powertrain, which consists of three main components: Sub-systems of the electric vehicle include the electric motor, battery and power electronics. It is necessary to realize how these constituents function in order to comprehend the dynamics of EVs.

Electric Motor:

In an EV, electric motor records electrical energy and converts it into mechanical energy that turns the wheel. Compared to internal combustion engines, electric motors offer an ability to produce an adjustable amount of torque, and its result, acceleration. There are different types of electric motors used in EVs, including:There are different types of electric motors used in EVs, including:

DC Brushless Motors: These are characteristic to modern EVs due to their effectiveness and resource durability.AC Induction Motors: These engines are characterized by their strength and efficiency in creating high power density.

Battery:

The battery is the power pack of the electric motor concerned. Almost every EV employs lithium-ion BMS due to high energy density and BMS lifespan. Key characteristics of EV batteries include:Key characteristics of EV batteries include:

Capacity: Expressed in kilowatt-hour (kWh), it defines the range of the vehicle.

Charging Time: Different based on the battery capacity and charging type whether it is Level 1, Level 2, or DC fast charging.

Lifecycle: The amount of times a battery or a capacitor could be charged and discharged before its capacity decreases considerably.

Power Electronics:

Interfaces control the amount of electricity to be supplied to the motor from the battery by power electronics. They rectify DC from the battery to AC for the motor and the speed and the torque of the motor are regulated by an inverter.

How EVs Work

Whenever you step on an accelerator pedal in an EV, power electronics take electrical energy from the battery and supplies it to an electric motor. The motor transforms this energy to mechanical energy to turn the wheels in the vehicle for motion or to do other jobs. These electric vehicles also employ regenerative braking mechanism that converts the energy used while braking to additional energy that can be charged to the battery.

Mechanical Engineering Insights

From a mechanical engineering perspective, several challenges and opportunities arise in the design and optimization of EVs:From a mechanical engineering perspective, several challenges and opportunities arise in the design and optimization of EVs:Thermal Management:

Therefore, the battery application requires effectiveness in managing thermal system in order to sustain the battery function and its life span. Besides cooling, several other measures are employed by engineers such as the use of liquid coolants and phase change materials.Lightweight Materials:

When weight of an EV is decreased, it is said that, the efficiency and the range of the EV is also increased. Vehicle engineers examine the application of such materials as aluminum, carbon fiber and other advanced composites within the car structure.Aerodynamics:

The streams of aerodynamic engineering target the minimization of drag and hence the energy dissipation on the electric vehicles. Engineers rely on computational flow dynamics cfd analysis to optimize the design of the vehicle body for aerodynamics.Future Developments

The field of electric vehicles has already advanced, and the research and development process continues to provide solutions to the issues found in the current designs and improve its performance. Some promising areas of development include:Some promising areas of development include:

Solid-State Batteries: They do claim to offer same or even better features such as energy density, charge time, and safety as the normal Lithium ion batteries.

Wireless Charging: Currently, other technologies such as wireless charging are still under development areas but in future they can be used to enhance the charging of EVs.

Autonomous Driving: The ADAS and autonomous driving features could enhance the effectiveness and safety of driving electric vehicle when incorporated into them.

Conclusion

Thus, electric automobiles are an innovation in the automotive sector instigated through mechanical engineering development and technology. However, as we keep on enhancing the design and the features of the EVs they will remain a key aspect of our sustainable future. Thank you for your attention to this post Today for you mechanical engineering fans, you will have the ability to see all the latest in mechanical engineering technologies and the ways that they’re being used.

.png)

.png)

0 Comments